- HOME

- COMPANY

- SENSORS AND INSTRUMENTS

-

AVIATION ENGINE DERIVATIVE MECHANICAL AND ELECTRICAL PRODUCTS

-

COOPERATIVE PARTNER

-

CONTACT US

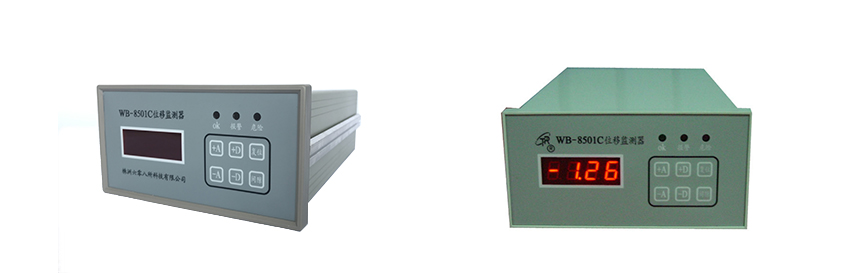

WB-8501C axial displacement monitor is an ideal instrument for measuring axial displacement of rotating machinery, which is used together with eddy current sensor.

WB-8501C axial displacement monitor can be widely used in the measurement and protection control of the axial displacement of rotating machinery in power generation, petroleum, chemical industry, metallurgy and other departments.

Application Introduction:

Fault monitoring:

Monitor the rotor axial position of rotating machinery (eddy current sensor).

Measurement parameters:

The position (displacement) of the rotor relative to the bearing shell.

Unit type:

Monitoring of various rotating machines. Such as steam turbine, fan, compressor, motor, pump, etc.

Installation requirements:

For units with existing eddy current probe system, it is only necessary to connect the wires and set alarm and danger points.

Main performance indexes:

Power supply: 220VAC

Input impedance: 10K Ω

Frequency response: 0 ~ 10kHz

Display mode: three and a half LED digital display

Accuracy: indication error ≤ 1%; standard output ≤ 1%

Output signal: Voltage 1 ~ 5V, output load ≥ 1K Ω;

Current 4 ~ 20mA, output load ≤ 500 Ω

Alarm shutdown: two levels, setting range is 5% ~ 100% of the range

Relay contact capacity: 28vdc, 5A or 115VAC, 0.5A

Boundary dimension: 270 (L) × 160 (W) × 80 (H) (unit: mm)

Installation dimension: (150 + 1) (width) × (74 + 1) (width) (unit: mm)

Weight: 2kg

Operating environment: temperature: - 10 ~ 50 ℃; humidity: < 80%

Storage temperature: - 20 ~ 75 ℃