- HOME

- COMPANY

- SENSORS AND INSTRUMENTS

-

AVIATION ENGINE DERIVATIVE MECHANICAL AND ELECTRICAL PRODUCTS

-

COOPERATIVE PARTNER

-

CONTACT US

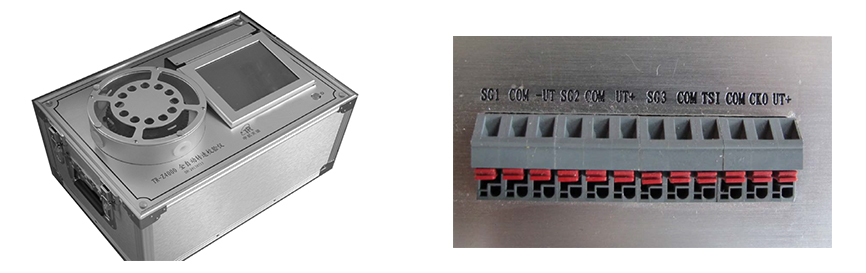

TR-Z4000 automatic speed calibrator realizes the automatic calibration of amplitude and frequency characteristics of eddy current and magnetoelectric speed sensors. The calibrator can intelligently draw, store and print the amplitude and frequency characteristics of the calibrated speed sensor.

TR-Z4000 automatic speed calibrator is equipped with a 7.5-inch TFT touch screen with a resolution of 640 × 480. U disk storage, with standard USB mouse interface. Built in high-speed data acquisition unit and upload data to PC (laptop) through data line to print various data curve reports offline.

Application Description:

In the tr-z4000 automatic speed calibrator system, the motor drive adopts two pole rotary and closed-loop drive control (military radar control technology) to drive the gear wheel. The speed range is 1R / min ~ 10000r / min, and the accuracy is 0.05%. The speed can be set digitally, and the setting accuracy is 1R / min.

Tr-z4000 automatic speed calibrator speed gear plate realizes software simulation to set the number of teeth, forward / reverse speed verification, the number of teeth can be set arbitrarily (1-255), and solves the problem of multiple tooth number verification.

The dynamic data is collected by 500ksps 16 bit a / D with high speed and high precision. The dynamic amplitude frequency characteristic data can be communicated to PC through network cable and run on PC.

Main performance indexes:

1. A gear disk is provided with module of 2.25. The number of teeth can be set as 60 / 134 / 30 or any other number of teeth (1-255). Material: AISI 4140 steel (International Standard).

2. Speed calibration range: 1R / min ~ 10000r / min, resolution: 1R / min.

3. It is applicable to the verification of eddy current speed sensors / passive / active magnetoelectric speed sensors and systems such as medium 5, medium 8 and medium 11.

4.7.5-inch TFT touch screen with resolution of 640 × 480 and refresh frequency of 5ms.

5. Various calibration data of common network cable communication, and output and print speed waveform and relevant data by PC (notebook computer).

6. Provide + 24VDC / - 24VDC two-way DC power supply (the maximum output current is 30mA, ripple is 5mv), which can be used for independent calibration of sensors.

7. Power supply of calibrator: 220VAC ± 10%, maximum working current 800mA. (10a fuse is recommended).

8. Size: 482mm × 332mm × 340mm (L × w × h).

9. The verification data can be stored in U disk and copied to PC.

10. The lower computer can be connected to the mouse for operation.